METEORIET II (MEms TEst voor hOog-volume Innovatieve ElektRonIschE Toepassingen II)

In Meteorite II we design structures to be ‘inserted’ on an early production stage (wafer level) and tests to serve as process control monitors of the wafer quality after front-end.

Questions?

Contact us.

dr. Yulia Tykhonenko Polishchuk

Project description

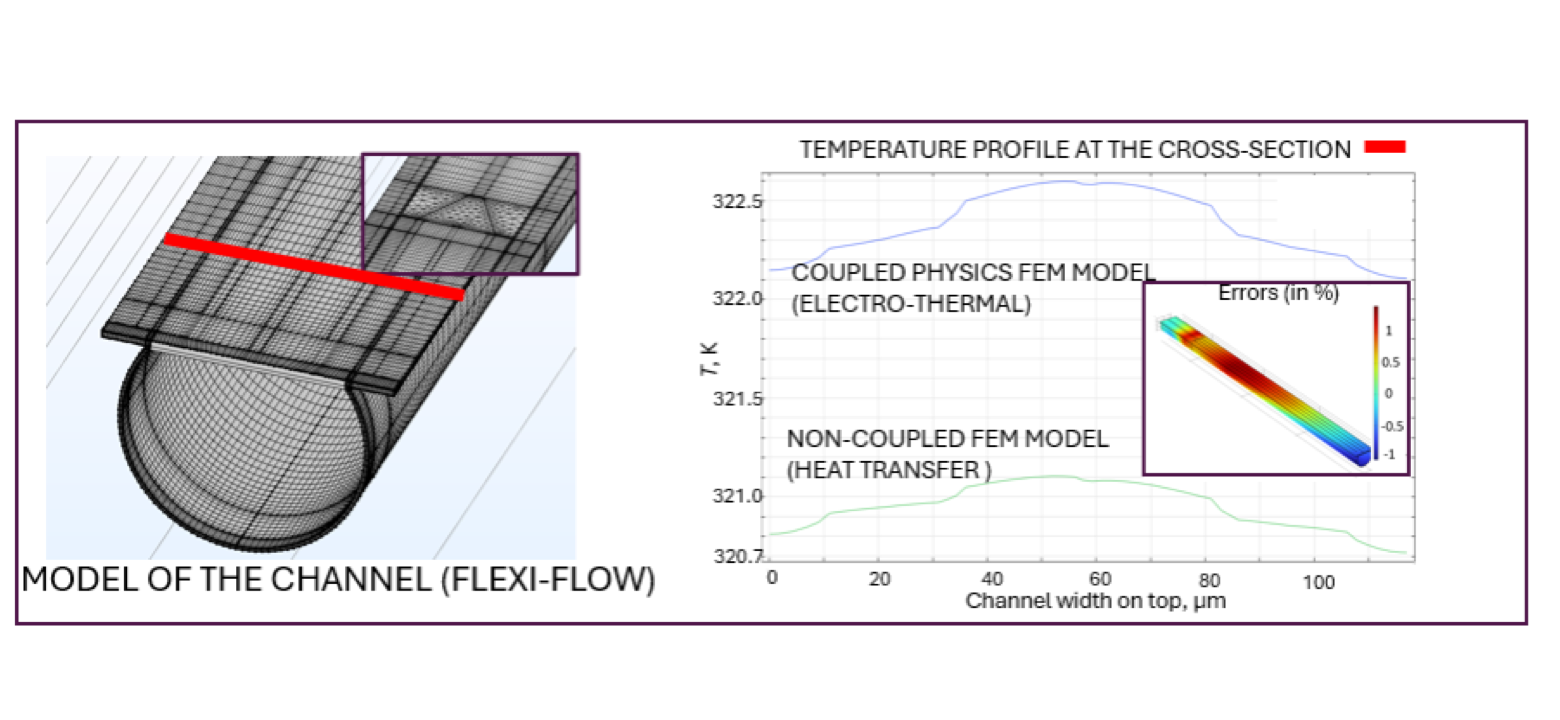

Thermal flow meters represent a vast range of sensors for applications in oil and gas, sustainable energy, food and medical care markets, where precise control of the mass flow is required. As a part of MEMS, the sensors are currently produced on wafers (front-end), sawn into individual chips (dice, back-end), assembled into modules (assembly), and then the product is tested. Due to high customization and complexity of MEMS technology there are no common test structures that can be ‘inserted’ into the production flow at earlier stages. For some products this results in only half of the chips being approved after testing (low yield). Increasing the technological impact and integrating more varied functions on the chips in turn lead to reduction of the available footprint for devices, and therefore, constrains on potential space for testing. One of the governing factors of the flow meters’ performance are material properties that are sensitive to variations in process (conditions).

In Meteorite II we develop the test structures to be ‘inserted’ and determine effective properties on a wafer, serving as process control monitors of wafers quality after front-end production and binning of produced devices based on their measured quality.

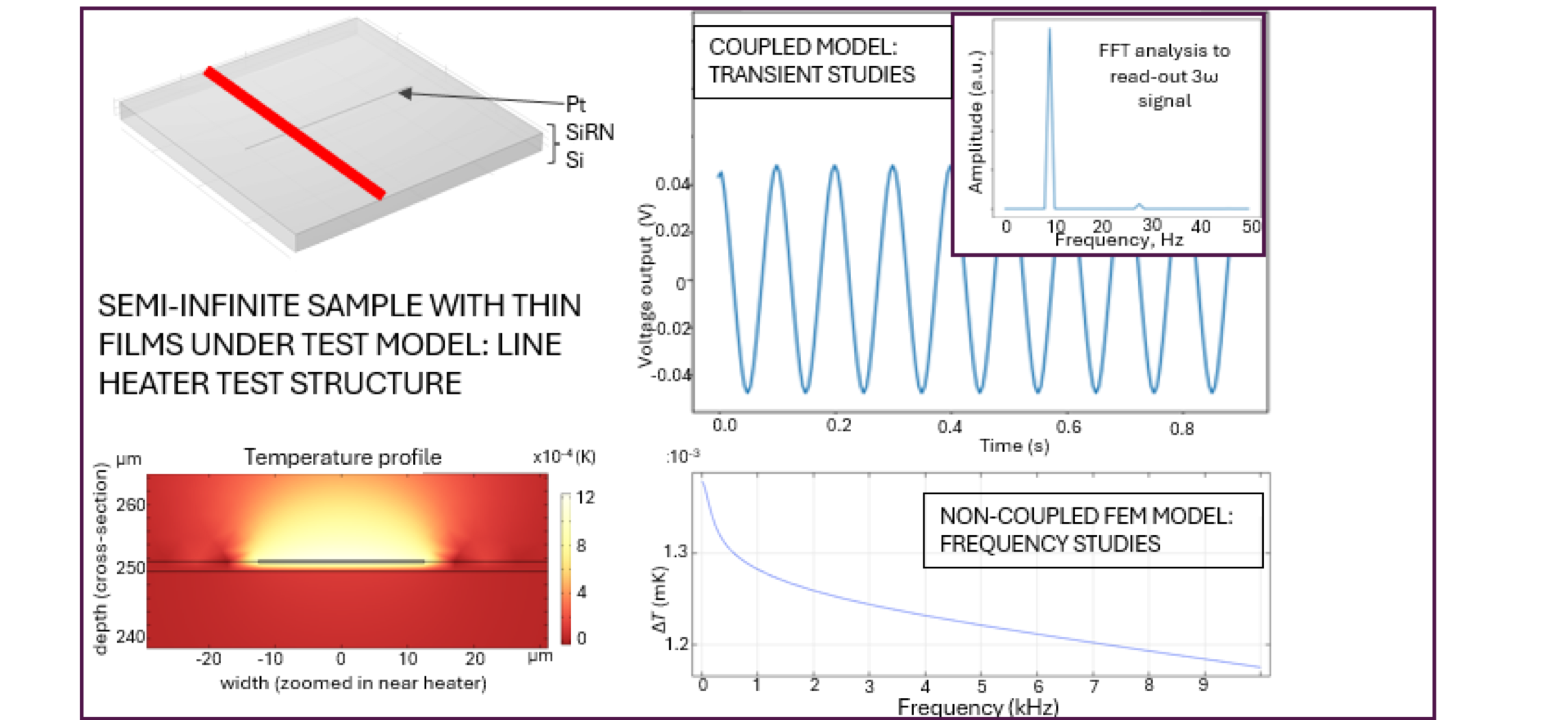

Specifically, we target the thermal properties of the flow meter’s material stack, i.e. thermal conductivity and heat capacity. For this we use 3ω-techniques and design various test structures (here, heater geometries). Being constrained by chip space, we also explore test structures that can combine multiple functionalities.

In this research project together with our industrial project partners we work on bringing this technology to a higher TRL level, facilitating scale-up and reducing the costs of MEMS products.

ANT Research line

More than Moore

Involved group members:

dr. ir. Aleksandar Andreski

Associate Lector Applied Nanotechnology

[email protected] Profile LinkedIn